mbs impact modifier

mbs impact modifier Specification

- Shelf Life

- 2 Years

- Application

- Industrial

- Physical Form

- Powder

- Density

- 0.92 Gram per cubic centimeter(g/cm3)

- Storage

- Room Temperature

- Product Type

- General chemical

- HS Code

- 390290

- Poisonous

- NO

- Appearance

- Powder

- Properties

- MBS is a core-shell structure modifier that achieves highly efficient toughening. Its most significant characteristic is its ability to significantly improve the toughness of plastics such as PVC while maintaining excellent transparency and surface gloss. Therefore, it is mainly used in indoor PVC products where high transparency and appearance are required, especially in food packaging and daily necessities. However, its weakness in UV resistance limits its application in long-term outdoor use scenarios.

- Smell

- Other

- Taste

- Other

- Purity

- 100%

- Usage

- mix

- Shape

- Granules

- CAS No

- 25053-09-2

About mbs impact modifier

MBS is a core-shell structured polymer impact modifier.

Methyl methacrylate forms the outer shell. Its main function is to provide good compatibility, gloss, and processing flow with matrix resins such as PVC. Butadiene forms the core rubber compound. Its function is to absorb and disperse impact energy, which is key to improving toughness. Styrene is often copolymerized with butadiene to form the rubber core (styrene-butadiene rubber), or participates in the composition of the shell to adjust properties.

II. Main Characteristics

1. Excellent toughening effect: Significantly improves the notched impact strength of plastics such as rigid PVC.

2. Good transparency: Due to its core-shell structure and the similarity of the outer shell's refractive index to PVC, MBS is the preferred impact modifier for transparent products.

3. Improved processability: Promotes plasticization, reduces melt viscosity, and makes processing easier.

4. High surface gloss: Suitable for products with high surface appearance requirements.

5. Some chemical resistance: However, it is not resistant to ultraviolet light (due to the presence of unsaturated double bonds in butadiene), and long-term outdoor use will cause yellowing and performance degradation. III. Main Application Areas

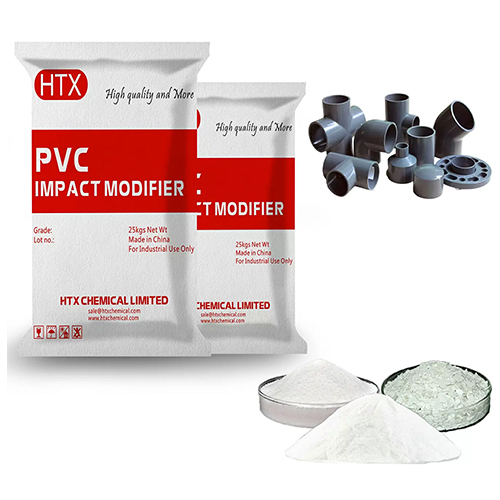

MBS is one of the most widely used impact modifiers in rigid and semi-rigid PVC products, especially in applications requiring transparency.

1. Packaging Materials:

Transparent Sheets/Films: Used for food packaging (e.g., fresh produce trays, pastry boxes), blister packaging (pharmaceuticals, cosmetics), credit card lamination, etc.

Bottles: Transparent PVC water bottles, cooking oil bottles, cosmetic bottles, etc.

2. Daily Consumer Goods:

Stationery: Transparent folders, rulers.

Household Items: Anti-slip mats, bathroom curtains, etc.

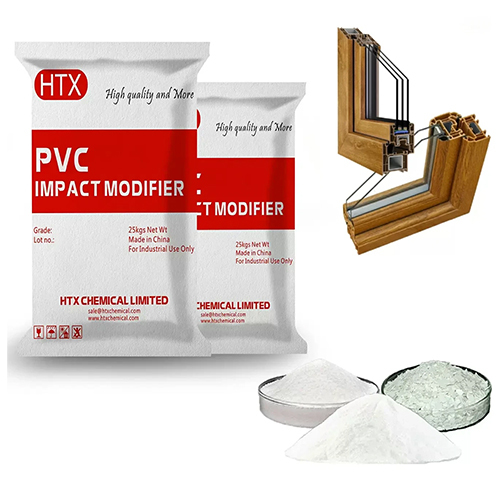

3. Building Materials (Indoor Use Only):

Decorative Panels: Interior ceilings, wall panels.

Pipes and Fittings: Some indoor pipes requiring transparency or high gloss.

Injection Molded Products: Appliance housings, accessories, etc.

4. Others:

Blended with engineering plastics such as PC and PET to improve their low-temperature brittleness.

MBS is a core-shell structure modifier that achieves highly efficient toughening. Its most significant characteristic is its ability to significantly improve the toughness of plastics such as PVC while maintaining excellent transparency and surface gloss. Therefore, it is mainly used in indoor PVC products where high transparency and appearance are required, especially in food packaging and daily necessities. However, its weakness in UV resistance limits its application in long-term outdoor use scenarios.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PVC Impact Modifier Category

ACM impact moodifier

Price 1050.0 USD ($) / Ton

Minimum Order Quantity : 1 Ton

Physical Form : Powder

Product Type : General chemical

Storage : Room Temperature

Application : Industrial

Chlorinated Polyethylene

Price 1600 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Physical Form : Powder

Product Type : Chlorinated Polyethylene

Storage : Room Temperature

Application : Industrial

Acrylic Impact Modifier

Price 1600 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Physical Form : Powder

Product Type : Acrylic Impact Modifier

Storage : Room Temperature

Application : Industrial

MBS Impact Modifier

Price 1600 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Physical Form : Powder

Product Type : Impact Modifier

Storage : Room Temperature

Application : Industrial