Acrylic Impact Modifier

Acrylic Impact Modifier Specification

- Purity

- 99.9%

- Physical Form

- Powder

- Poisonous

- NO

- Taste

- Odorless

- Storage

- Room Temperature

- Product Type

- Acrylic Impact Modifier

- Grade

- Industrial

- Application

- Industrial

- Appearance

- Powder

Acrylic Impact Modifier Trade Information

- Minimum Order Quantity

- 10 Tons

- Supply Ability

- 100000 Tons Per Month

- Delivery Time

- 3 Week

About Acrylic Impact Modifier

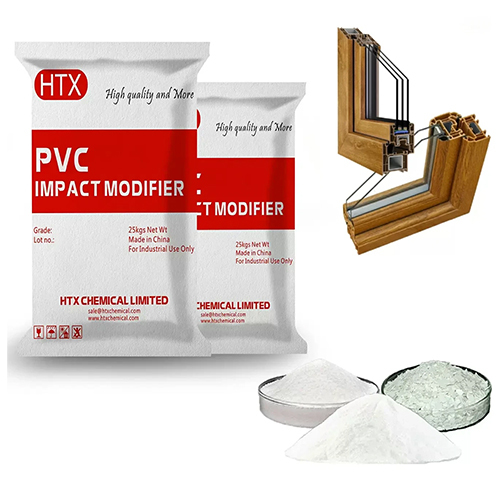

Product Overview ACRYLIC impact modifier is a polymer additive based on acrylic core-shell structure, designed specifically to enhance the impact toughness of PVC, especially hard PVC. Its unique core-shell microstructure (hard core+soft shell) can form an elastic dispersed phase in the PVC matrix, effectively absorbing impact energy, significantly improving the materials impact resistance, while maintaining excellent weather resistance and processing stability. Core Features: Ultra high impact resistance The notch impact strength of PVC can be increased to 20-60 kJ/m2(unmodified PVC typically <5 kJ/m2). It maintains toughness at low temperatures (-30 DegC to -40 DegC) and is suitable for cold environments. Excellent weather resistance Does not contain unsaturated double bonds (different from MBS/ABS), has excellent UV aging resistance, and does not turn yellow after long-term outdoor use. Suitable for products such as door and window profiles, outdoor building materials, etc. that are exposed to sunlight and rainwater. Transparency optionalSome models have a refractive index that matches PVC and can be used for high transparency products such as medical packaging and transparent sheets. Processing compatibility Good compatibility with PVC resin, stabilizers, and lubricants, without affecting plasticization efficiency. Some models also serve as processing aids, such as promoting melting and improving surface smoothness. Rigid toughness balanceWhile improving toughness, it has little impact on the rigidity (bending modulus) of PVC, making it suitable for structural components. Applications Industry Application Scenarios Core Requirements Building materials Door and window profiles, PVC tiles, guardrails Weather resistance, high impact resistance Automobile Instrument panel, sealing strip, interior trim Low temperature toughness, anti-aging Packaging Transparent medical packaging, food containers Transparent, no precipitation Electronics Electrical enclosures, junction boxes Flame retardant synergy (can be paired with flame retardants SummaryACRYLIC impact modifier is the preferred choice for high-end rigid PVC products, especially suitable for applications that require weather resistance, high impact resistance, and low temperature toughness (such as door and window profiles, automotive components). Although the cost is higher than CPE/MBS, its comprehensive performance advantages can significantly extend product life and reduce long-term maintenance costs. For transparent or extremely low-cost requirements, MBS or CPE can be chosen as alternative solutions at discretion.FAQs of Acrylic Impact Modifier:

Q: What is the physical form of Acrylic Impact Modifier?

A: The physical form of Acrylic Impact Modifier is powder.Q: Is Acrylic Impact Modifier poisonous?

A: No, Acrylic Impact Modifier is not poisonous.Q: What is the purity level of Acrylic Impact Modifier?

A: The purity level of Acrylic Impact Modifier is 99.9%.Q: What is the recommended storage condition for Acrylic Impact Modifier?

A: Acrylic Impact Modifier should be stored at room temperature.Q: What is the grade of Acrylic Impact Modifier?

A: The grade of Acrylic Impact Modifier is industrial.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PVC Impact Modifier Category

mbs impact modifier

Price 2000.0 USD ($) / Kilograms

Minimum Order Quantity : 800 Kilograms

Physical Form : Powder

Shelf Life : 2 Years

Storage : Room Temperature

HS Code : 390290

ACM impact moodifier

Price 1050.0 USD ($) / Ton

Minimum Order Quantity : 1 Ton

Physical Form : Powder

Shelf Life : 2 Years

Storage : Room Temperature

HS Code : 390690

Chlorinated Polyethylene

Price 1600 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Physical Form : Powder

Storage : Room Temperature

Impact modifier for pvc pipes

Price 125000.0 INR / Ton

Minimum Order Quantity : 1 Ton

Physical Form : Powder

Shelf Life : 2 Years

Storage : Room Temperature

HS Code : 3906909090