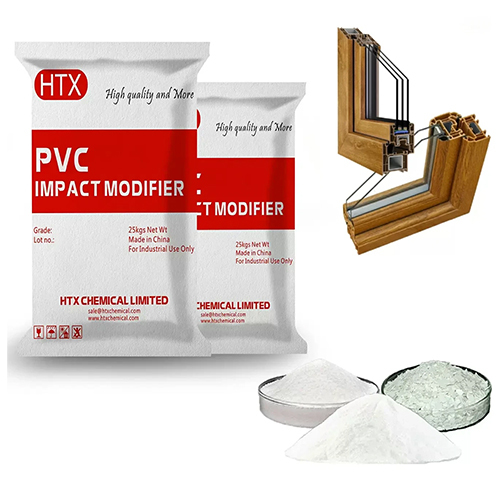

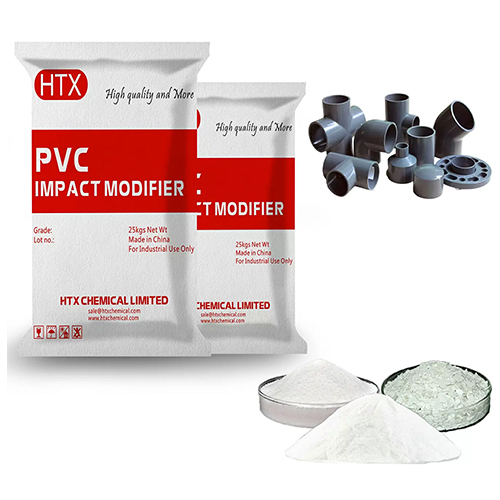

MBS Impact Modifier

MBS Impact Modifier Specification

- Taste

- Odorless

- Storage

- Room Temperature

- Purity

- High

- Product Type

- Impact Modifier

- Application

- Industrial

- Grade

- Industrial

- Appearance

- Powder

- Poisonous

- NO

- Physical Form

- Powder

MBS Impact Modifier Trade Information

- Minimum Order Quantity

- 10 Tons

- Supply Ability

- 100000 Tons Per Month

- Delivery Time

- 3 Week

About MBS Impact Modifier

Product Overview MBS impact modifier is a core-shell polymer of methyl methacrylate butadiene styrene ternary copolymer, specifically designed to enhance the impact resistance of transparent/semi transparent PVC products. Its unique "hard shell soft core" microstructure makes it the only PVC modifier that can simultaneously meet high transparency and high impact resistance requirements. Key characteristic parameters: Core shell structure: Core layer: Butadiene rubber phase (providing toughness) Shell: MMA/ST copolymer (ensuring compatibility) Refractive index: 1.52-1.54 (perfectly matched with PVC 1.52-1.55) Particle size distribution: 0.1-0.3 u m (optimal light scattering control) Glass transition temperature: Core layer: -80DegC (low temperature impact resistance) Shell: 105DegC (thermal stability) Core functional advantages: Excellent optical performance Transmittance>90% (550nm wavelength) Haze<5% (2mm thick sample) Can prepare medical grade transparent products Efficient toughening effect Increase gap impact strength by 10-20 times Maintain good toughness at -10 oC Processing adaptability Wide melting temperature range (160-200 oC) Good compatibility with PVC melt Typical application areas: Transparent products (main applications) Medical packaging: infusion bags/bottles (dosage 8-12 phr) Food packaging: transparent container/cling film (5-10 phr) Daily necessities: cosmetic bottles/stationery (6-10phr) Special requirements products Electrical panel (flame retardant model required) Automotive interior parts (low temperature resistant models) Instrument window (ultra-high transparency model) Comparison with competitors: Features MBS ACR CPE Transmittance (%) 90+ 75-85 Opaque Anti impact enhancement factor 10-20x 8-15x 5-10x Weather resistance 2 Stars 6 Stars 5 Stars Cost 3 Stars 4 Stars 2 Stars Applicable temperature -1070 DegC -3080 DegC -2060 DegC MBS impact modifier achieves ABS grade impact strength by precisely controlling the core-shell ratio and particle size distribution, while maintaining the original transparency of PVC. It is currently an irreplaceable key modified material for transparent PVC products. With the increasing demand for medical packaging and high-end food packaging, this product is developing towards a cleaner and more specialized direction.FAQs of MBS Impact Modifier:

Q: What is the physical form of MBS Impact Modifier?

A: The physical form of MBS Impact Modifier is powder.Q: Is MBS Impact Modifier poisonous?

A: No, MBS Impact Modifier is not poisonous.Q: What is the grade of MBS Impact Modifier?

A: The grade of MBS Impact Modifier is industrial.Q: What is the taste of MBS Impact Modifier?

A: MBS Impact Modifier is odorless and does not have a taste.Q: How should MBS Impact Modifier be stored?

A: MBS Impact Modifier should be stored at room temperature.Q: Does MBS Impact Modifier have high purity?

A: Yes, MBS Impact Modifier has high purity.Q: What is the appearance of MBS Impact Modifier?

A: The appearance of MBS Impact Modifier is powder.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PVC Impact Modifier Category

ACM impact moodifier

Price 1050.0 USD ($) / Ton

Minimum Order Quantity : 1 Ton

Physical Form : Powder

Shelf Life : 2 Years

Storage : Room Temperature

HS Code : 390690

Chlorinated Polyethylene

Price 1600 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Physical Form : Powder

Storage : Room Temperature

ACM IMPACT MODIFIER

Price 110000.0 INR / TON

Minimum Order Quantity : 1 TON

Physical Form : Powder

Shelf Life : 2 Years

HS Code : 3901909000

Impact modifier for pvc pipes

Price 125000.0 INR / Ton

Minimum Order Quantity : 1 Ton

Physical Form : Powder

Shelf Life : 2 Years

Storage : Room Temperature

HS Code : 3906909090