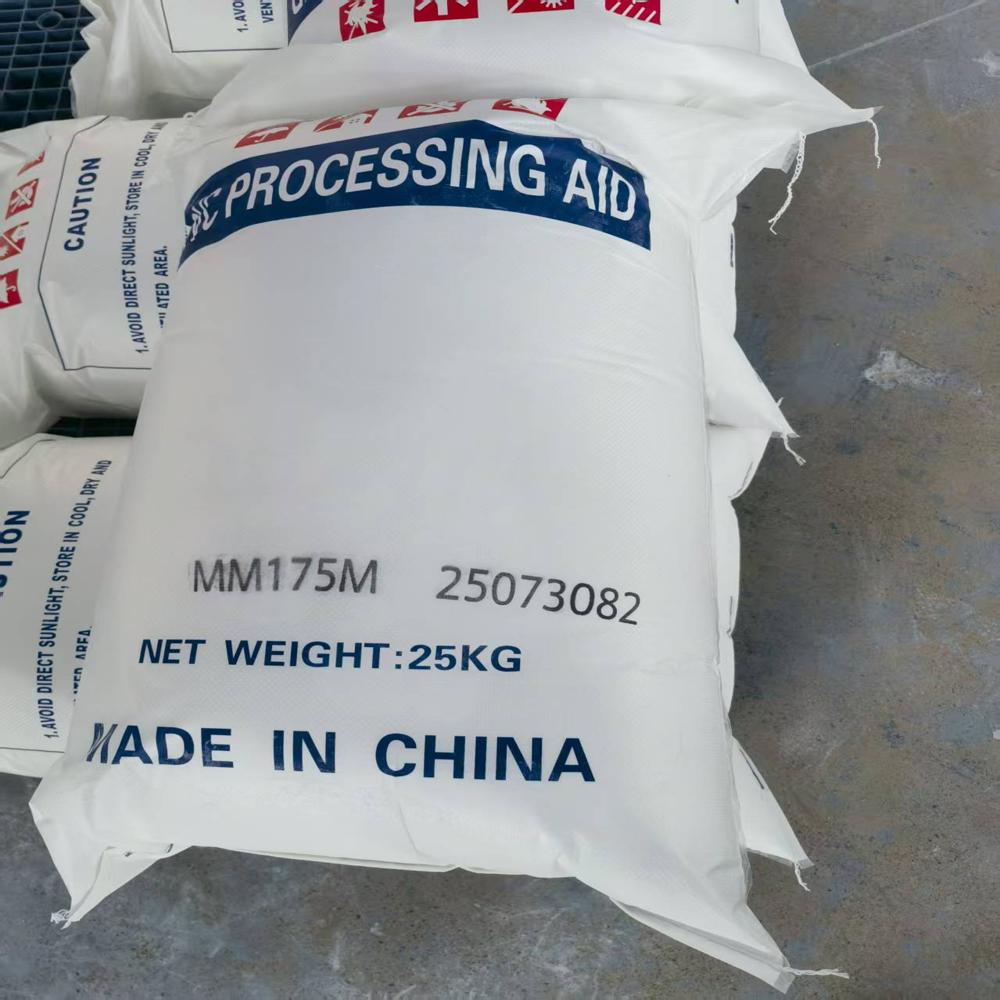

ACM IMPACT MODIFIER

ACM IMPACT MODIFIER Specification

- HS Code

- 3901909000

- Physical Form

- Powder

- Product Type

- CHEMICAL

- Shelf Life

- 2 Years

- Properties

- ACM impact modifier is an essential additive for manufacturing high-performance, highly weatherable rigid PVC outdoor products. Its unique "core-shell" structure significantly enhances the material's toughness while imparting unparalleled UV and aging resistance. While relatively expensive, it offers a highly cost-effective option for outdoor applications requiring long service life and reliability.

About ACM IMPACT MODIFIER

ACM stands for acrylic copolymer. As an impact modifier, it is a polymer used to improve the impact resistance of plastics, particularly rigid polyvinyl chloride (PVC) products. When a PVC product is subjected to an impact, ACM absorbs and dissipates the impact energy through its deformation, significantly reducing the risk of cracking or rupture.

Core Functions and Mechanism of Action

1. Main Function

Significantly Improves Impact Strength: This is its core function, capable of multiplying the notched impact strength of rigid PVC.

Improves Weatherability: ACM contains no unsaturated double bonds, resulting in exceptional UV and aging resistance. This is its most significant advantage over CPE and MBS impact modifiers.

Minor Impact on Transparency: While not as capable of producing ultra-high-transparency products as MBS, ACM can produce translucent products (such as corrugated board) where transparency requirements are less stringent.

Excellent Processability: It exhibits excellent compatibility with PVC and is easily plasticized and dispersed.

2. Mechanism of Action (Core-Shell Structure)

Most highly effective ACM impact modifiers utilize a classic core-shell structure:

Shell: Typically composed of an acrylic polymer with a high glass transition temperature. This polymer exhibits excellent compatibility with PVC resin, allowing it to be evenly dispersed in the PVC matrix and forming a strong bond with the PVC molecular chains.

Core: Typically composed of an acrylic elastomer with a lower glass transition temperature. This soft "core" acts as a stress concentrator. When the material is impacted, it induces crazing and shear banding, absorbing significant impact energy.

Simply put, the hard "shell" ensures integration with the PVC, while the soft "core" is responsible for sacrificing itself to absorb impact.

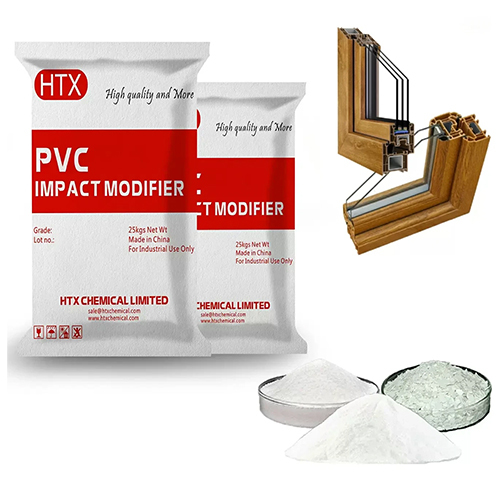

Typical Applications

Due to its excellent weather resistance, ACM impact modifiers are primarily used in rigid PVC products for outdoor use:

PVC outdoor architectural profiles: Such as door and window profiles, awnings, and guardrails. This represents the largest application area for ACM.

PVC corrugated sheets/roofing panels: Require high weather resistance and a certain degree of impact resistance.

PVC pipes: Especially for piping systems exposed outdoors.

PVC advertising boards and exterior wall cladding.

Other rigid PVC products that require long-term outdoor use and have high requirements for impact resistance and aging resistance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PVC Impact Modifier Category

mbs impact modifier

Price 2000.0 USD ($) / Kilograms

Minimum Order Quantity : 800 Kilograms

Physical Form : Powder

Storage : Room Temperature

Appearance : Powder

Taste : Other

ACM impact moodifier

Price 1050.0 USD ($) / Ton

Minimum Order Quantity : 1 Ton

Physical Form : Powder

Storage : Room Temperature

Appearance : powder

Taste : Other

Acrylic Impact Modifier

Price 1600 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Physical Form : Powder

Storage : Room Temperature

Appearance : Powder

Taste : Odorless

Chlorinated Polyethylene

Price 1600 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Physical Form : Powder

Storage : Room Temperature

Appearance : Powder

Taste : Odorless