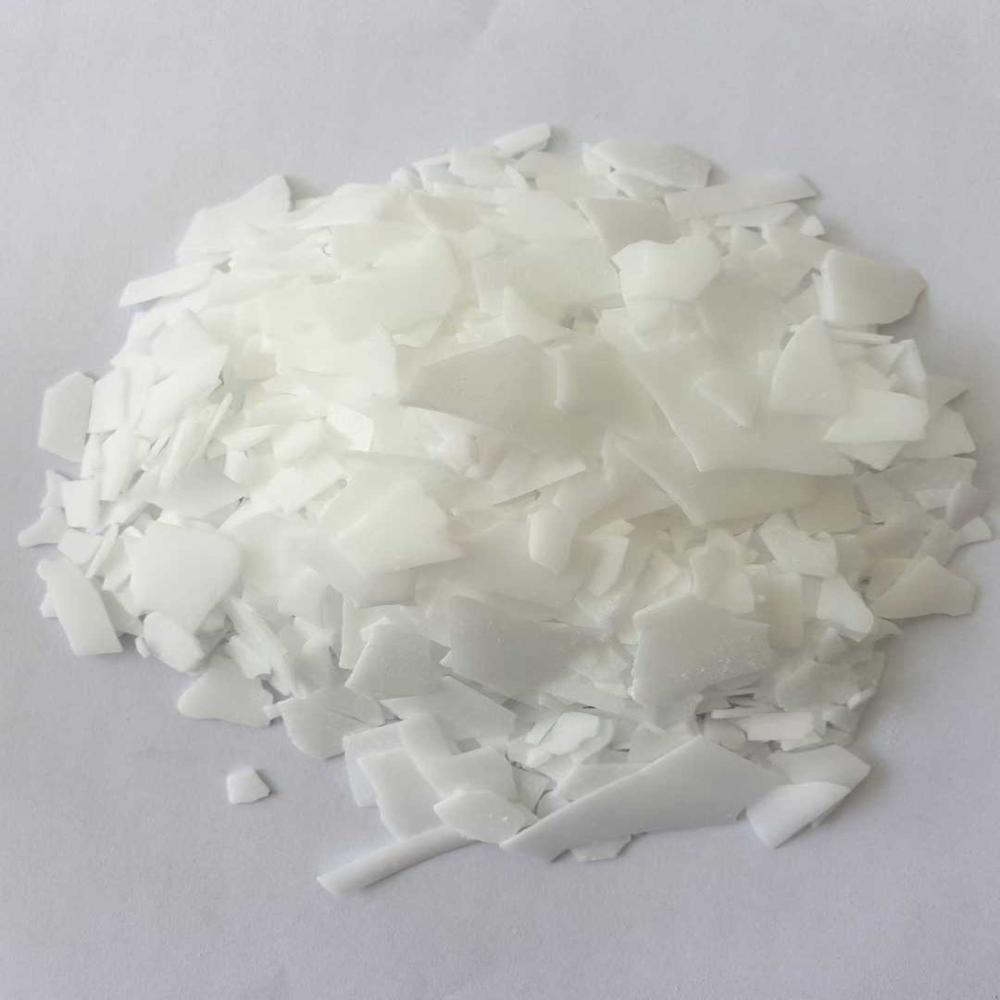

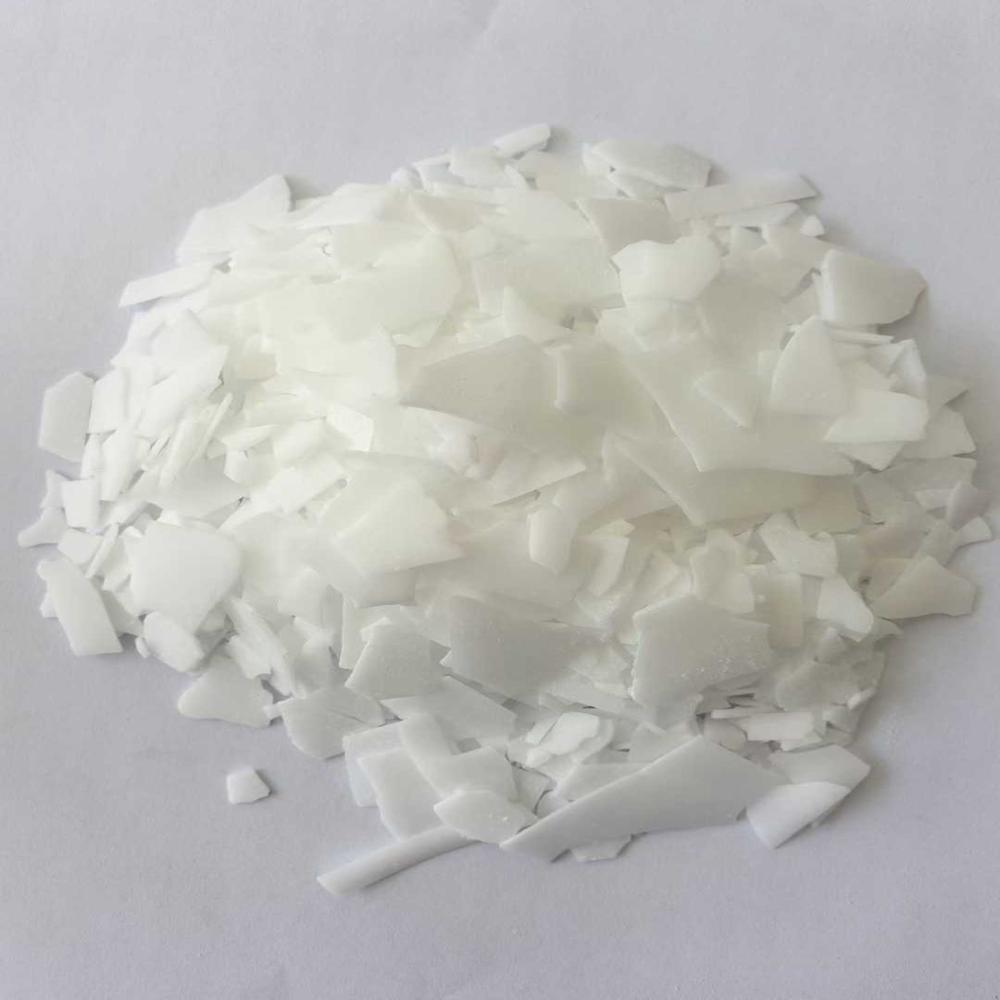

pvc compound stabilizer

pvc compound stabilizer Specification

- Form

- Powder

- Melting Point

- PVC compound stabilizer

- HS Code

- 3812399000

- Chemical Name

- PVC stabilizer

- Grade

- Industrial Grade

- Usage

- 3.0~5.0

- Application

- Industrial

- Non Toxic

- Yes

About pvc compound stabilizer

PVC compound stabilizers are key additives in PVC plastic formulations. Their core function is to prevent PVC resin from degrading, discoloring, and experiencing performance decline during processing and use due to factors such as heat, light, and oxygen.

PVC resin itself has poor thermal stability. When the temperature exceeds approximately 160C (processing temperatures are typically 170-220C), the PVC molecular chain begins to decompose, releasing hydrogen chloride gas and causing the material to:

Discoloration: from yellow orange red brown black.

Performance degradation: decreased strength and toughness, rendering it unusable.

Processing difficulties: decomposition forms insoluble substances, affecting production continuity and product appearance.

Stabilizers are essential components to inhibit this chain reaction.

Main functions:

1. Absorbing HCl: Neutralizing the hydrogen chloride produced during decomposition, preventing its autocatalytic acceleration of decomposition.

2. Replacing unstable chlorine atoms: Some unstable chlorine atoms (such as allyl chloride) exist on the PVC molecular chain; stabilizers can react with them to form a more stable structure.

3. Antioxidant and UV Protection: Prevents PVC from aging due to oxidation and UV exposure.

4. Improved Processing Performance: Some stabilizers also act as lubricants, aiding in material melting and demolding.

5. Maintaining Product Color and Transparency: This is the most direct indicator of stabilizer efficiency.

In summary, PVC compound stabilizers are the technological cornerstone of the widespread application of PVC materials. From the initially toxic but highly effective lead salts, they have evolved to today's environmentally friendly and efficient systems such as calcium-zinc and organotin, continuously moving towards greater safety, efficiency, and specialization.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PVC Stabilizer Category

Lead Compound Stabilizer

Price 1550 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Application : Industrial

Storage : Keep away from moisture

Form : Powder

Purity : Very high

Ca Zn stabilizer

Price 1550 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Application : Industrial

Storage : Keep away from moisture

Form : Powder

Purity : Very high

one pack stabilizer for pvc pipe

Price 1600.0 USD ($) / Ton

Minimum Order Quantity : 1 Ton

Application : Plastic

Storage : Dry Place

Form : Powder

Purity : 100%

Lead stabilizer in PVC

Price 1500.0 USD ($) / Ton

Minimum Order Quantity : 1 Ton

Application : Plastic

Storage : Room Temperature

Form : Other