lead stabilizer in pvc

lead stabilizer in pvc Specification

- HS Code

- 381239900

- Solubility

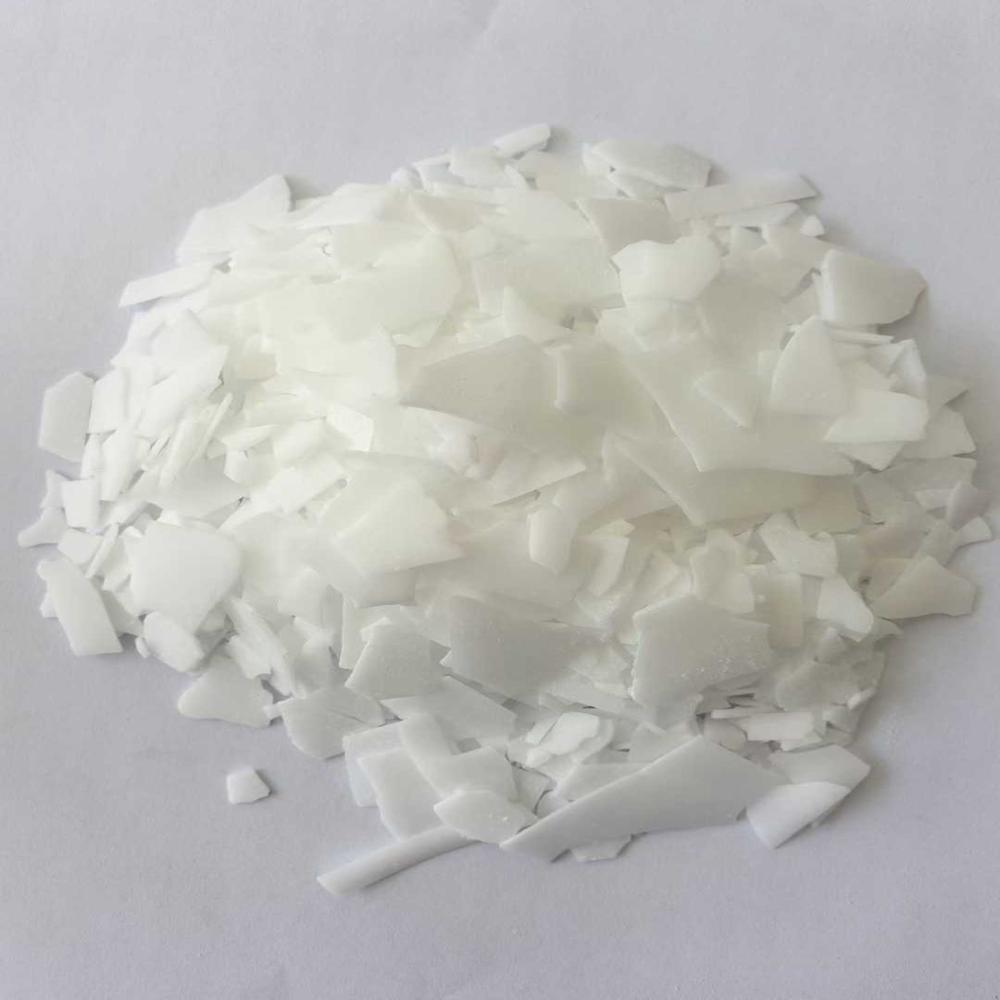

- Flake

- Application

- Plastic

About lead stabilizer in pvc

Lead stabilizers were once a dominant type of stabilizer in the polyvinyl chloride (PVC) industry. Their core value lies in their ability to efficiently solve the critical defect of poor thermal stability in PVC materials through chemical reactions (such as absorbing hydrogen chloride released during the thermal decomposition of PVC and replacing unstable chlorine atoms on the molecular chain), allowing for high-temperature processing. These stabilizers are represented by tribasic lead sulfate (with the best thermal stability) and dibasic lead phosphite (which also has weather resistance). Due to their excellent long-term thermal stability, superior electrical insulation, and low cost, they are widely used in key areas where transparency is not a requirement, such as wires and cables, building drainage pipes, and window and door profiles.Excellent thermal stability: Its long-term thermal stability ranks among the best of all stabilizers, making it particularly suitable for high-temperature processing environments.

Superior electrical insulation: Enables PVC products to maintain excellent electrical properties, making it the preferred choice for wire and cable sheathing and insulation materials.

Good weather resistance: Provides products with excellent resistance to UV aging, suitable for profiles and pipes used outdoors for extended periods.

High cost-effectiveness: Relatively low cost per unit of stabilization efficiency, resulting in significant economic benefits in the long run.

Wide processing tolerance: Wide adaptability to PVC formulations, and relatively easy process control.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PVC Stabilizer Category

Lead Compound Stabilizer

Price 1550 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Form : Powder

Application : Industrial

Storage : Keep away from moisture

Grade : Industrial Grade

Ca Zn stabilizer

Price 1550 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Form : Powder

Application : Industrial

Storage : Keep away from moisture

Grade : Industrial Grade

one pack stabilizer for pvc pipe

Price 1600.0 USD ($) / Ton

Minimum Order Quantity : 1 Ton

Form : Powder

Application : Plastic

Storage : Dry Place

Grade : Industrial Grade

pvc compound stabilizer

Price 1550.0 USD ($) / Ton

Minimum Order Quantity : 1 Ton

Form : Powder

Application : Industrial

Grade : Industrial Grade